S92, en-route, south southwest of Stavanger Norway, 2020

S92, en-route, south southwest of Stavanger Norway, 2020

Summary

On 25 September 2020, a Sikorsky S92A returning from an offshore platform was in descent approximately 40nm from destination Stavanger when main gear box low pressure and left engine oil temperature cautions were annunciated. The affected engine was reduced to idle and a MAYDAY declared. A further related alert prompted descent to 200 feet and sixteen minutes after the initial malfunction, a normal landing was completed at Stavanger. A significant oil leak found in the main gear box was attributed to oil flow reduction and consequent overheating caused by a loose washer inadvertently left inside the gearbox during routine maintenance.

Flight Details

Aircraft

Type of Flight

Public Transport (Passenger)

Intended Destination

Take-off Commenced

Yes

Flight Airborne

Yes

Flight Completed

Yes

Phase of Flight

Descent

Location

Approx.

SSW of Stavanger, Norway

General

Tag(s)

Helicopter Involved

LOC

Tag(s)

Loss of Engine Power

EPR

Tag(s)

MAYDAY declaration

AW

System(s)

Engine Fuel and Control,

Rotary Aircraft Transmission

Contributor(s)

Component Fault in service,

Maintenance FOD

Outcome

Damage or injury

No

Non-aircraft damage

No

Non-occupant Casualties

No

Off Airport Landing

No

Ditching

No

Causal Factor Group(s)

Group(s)

Aircraft Technical

Safety Recommendation(s)

Group(s)

Aircraft Airworthiness

Investigation Type

Type

Independent

Cite This Page

SKYbrary Aviation Safety. (February 28, 2025). S92, en-route, south southwest of Stavanger Norway, 2020. EUROCONTROL.

Retrieved February 2, 2026

from https://skybrary.aero/accidents-and-incidents/s92-en-route-south-southwest-stavanger-norway-2020

UID: 35418

Copied!

COPY

Description

On 25 September 2020, a Sikorsky S92A (LN-ONQ) being operated by Bristow Norway on a North Sea offshore passenger transport flight from the West Elara oil platform to Stavanger had begun descent in day VMC when main gear box oil pressure and left engine oil temperature cautions were successively annunciated. Descent to 500 feet asl was made and a MAYDAY declared. When a more serious related warning then followed, further descent to 200 feet asl was made and maintained until reaching Stavanger, which was the nearest suitable landing option, where it became clear that a significant main gear box oil leak had occurred.

Investigation

The occurrence was immediately reported to the Norwegian Safety Investigation Authority and a Serious Incident Investigation was commenced with the CDFDR removed and secured the same day. All data subsequently downloaded was of good quality and useful to the Investigation.

It was noted that the 45 year-old Captain had a total of 6,300 hours flying experience which included 5,500 hours on type. He had joined Bristow Norway in 2008 as a First Officer and gained promotion to Captain in 2013. The 26 year-old First Officer had a total of 1,910 hours flying experience which included 1,280 hours on type. He had joined Bristow UK in 2018 and transferred to Bristow Norway in 2020.

What happened

A 2½ hour return flight to another offshore platform made by the crew in the same helicopter from Stavanger earlier in the day was uneventful. Their outbound 172 nm flight to the West Elara platform was then also completed without any problems. For the return to Stavanger with three passengers on board, a climb to and cruise at 7000 feet was also normal as was the descent until passing approximately 4,500 feet when a ‘MGB OIL PRESS’ Warning caution occurred. This indicated that the Main Gear Box oil pressure had dropped below 45 psi. As the Captain was completing the initial stages of the Emergency Checklist for this warning (see the illustration below), the indicated oil temperature continued to drop and an additional warning ‘INPUT/ACC# 1HOT’, which related to the excessive temperature of the oil being supplied to the left engine, appeared.

In accordance with this Checklist, the left engine was reduced to idle, the airspeed, to that applicable with one engine inoperative and the APU (which supplies electrical, pneumatic and hydraulic power to the helicopter’s systems) was started and a MAYDAY call made. It was decided to continue the already-established descent to 500 feet asl. When the MGB oil pressure reached 35 psi, the ‘MGB BYPASS’ caution illuminated, indicating that the oil cooler for the main gearbox was automatically disconnected and the descent was continued to 200 feet asl.

The QRH Emergency Checklist for the abnormal oil pressure/temperature warnings displayed. [Reproduced from the Official Report]

The passengers were then briefed to prepare for a possible ditching which requires them to pull their immersion suit hood over their heads, close the zip to establish an emergency breathing system and take up a crash position. In the context of this action, it was noted that a ditching “entails an increased risk of loss of life as the helicopter can overturn, fill with water and complicate an evacuation of both passengers and crew”.

The remainder of the planned flight was completed at this altitude and the ‘run-on’ landing at Stavanger was completed without further event sixteen minutes after the initial MGB low oil pressure warning had appeared. Accompanied by RFFS vehicles the helicopter then proceeded to its assigned parking position where all occupants exited normally. Oil could be seen coming from the vicinity of the left engine and running down the exterior of the fuselage along the cabin (see the illustration below). When the engine cover plates were opened, RFFS personnel measured temperatures of almost 250°C on the outside of the left main gearbox input module and noted smoke but no sign of fire. A subsequent check of the main gearbox oil level found that approximately 4 litres were missing and later examination of flight recorder data found that the highest recorded oil temperature was 214°C and the lowest recorded oil pressure was 28 psi.

The Helicopter after arrival at Stavanger showing evidence of the oil leak. [Reproduced from the Official Report]

The Investigation noted that although the flight time to landing could have been reduced by a few minutes by heading directly for the nearest land, such an off-airport landing could not have been carried out as a run-on landing. This meant that “it would have been necessary to re-accelerate the engine they had set to idle before landing and the load on the gearbox would have been greater”. This option would also have meant that no RFFS cover would have been available for the landing.

It was also observed that the checklist action calling for the left engine to be reduced to idle would have had “little or no effect on the temperature increase in the main gearbox” since idling the engine did not alter the rotational speed of all the main gearbox dynamic components. The only way to reduce increasing heat in the main gearbox would have been to reduce the power output from both engines.

It was noted that either a ‘MGB OIL OUT’ warning or an MGB OIL PRESS warning accompanied by both MGB OIL PRESS and MGB OIL HOT cautions at the same time as an oil pressure below 5 psi and an aural alert would have required an immediate landing/ditching. The Investigation did not subsequently attempt to calculate how long the flight could have continued before catastrophic faults occurred in the main gearbox.

Why it happened

An annotated illustration of the Main Gear Box and the two engine accessory modules is shown below. An initial examination at Bristow Norway found that most of the oil had leaked from the area where the left (no.1) engine drive shaft was attached to the no.1 input module. The indicator on the main gearbox oil filter showed that its oil filter was becoming clogged and the temperature in the left input module had been so high that “some plugs of sealing compound had come loose or been deformed”. An examination of the chip detectors in the main gearbox oil system did not find metal particles of any significance and nothing abnormal was found in respect of the drive shafts of the two oil pumps. However the main gearbox oil filter was found to contain abnormal-looking grey-brown oil inside the two filter elements although no visible particle contamination was found within them.

The Main Gearbox with the main rotor shaft emerging from the main gearbox module. [Reproduced from the Official Report]

The complete main gearbox was sent to Sikorsky in the USA for further examination overseen by the NTSB and selected findings in the Final Report of a three day examination of the gearbox included the following actions and findings:

- The left input and accessory modules were visually examined before disassembly with no unexpected or significant findings. An internal examination by borescope was then carried out and a loose washer was found in the input module’s scavenge oil passageway.

- The input module was disconnected from the accessory module and disassembled. Colour changes compatible with the influence of high temperatures were found on the inside of the input module.

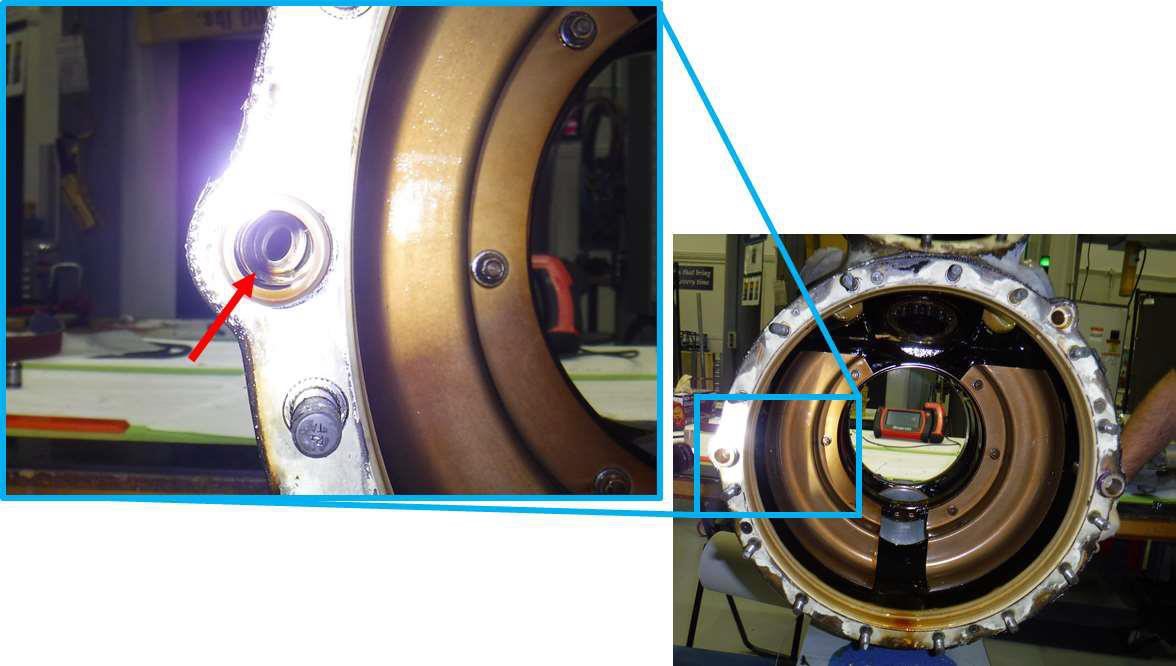

- Disassembly of the input module provided access to the washer, which was located approximately 76 mm inside the passageway where it was stuck - see the illustration below. The 3.40mm thick washer was removed and found to have an external diameter of 17.22 mm and an internal diameter of 10.90mm. The washer as found is shown below and was identifiable as P/N MS20002-6.

- The washer was not new and although evidence that it had previously been installed was found, how it might have reached its eventual position was not obvious from its discovery.

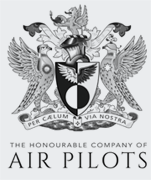

The recovered washer where found in the scavenge oil passageway of the left main gearbox input module. [Reproduced from the Official Report]

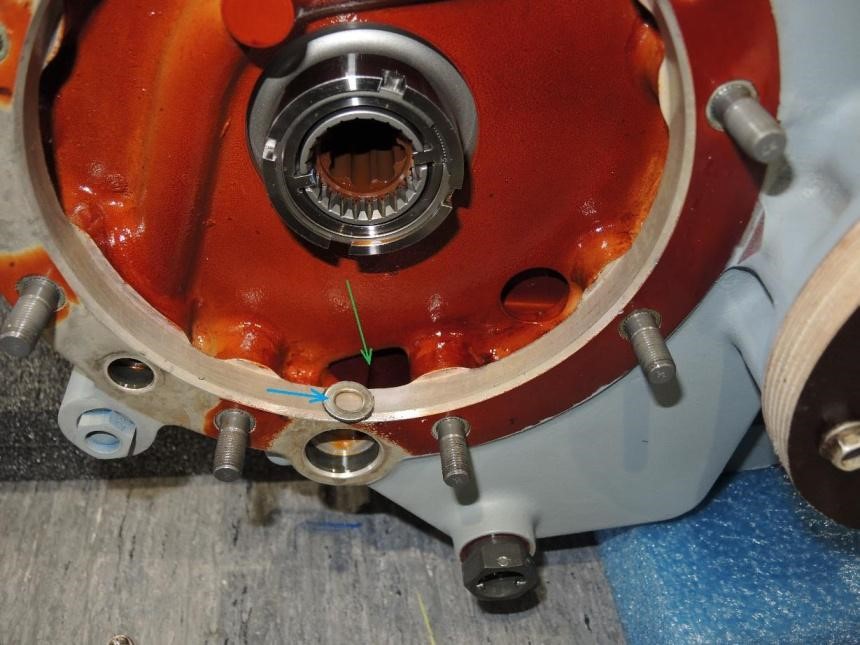

Given that the washer found was the only explanation for the raised gearbox oil temperature and pressure, the Investigation considered how the washer could have entered the input module. It was concluded that it would not have been possible for the washer (blue arrow) to have entered the oil passageway where it was found by moving from the main module since this would have been prevented by filtering screens. It was therefore concluded that it must have entered via openings such as the one (green arrow) exposed when the generator was disconnected from the flange of the accessory module (see the illustration below).

The accessory module flange where it is connected to the generator. [Reproduced from the Official Report]

It was not possible to establish when the washer entered the accessory module but relevant maintenance documentation showed that the most recent disconnection from the associated generator prior to the investigated event had been four months (and 487 hours 35 minutes engine running time) before it occurred.

Whilst the washer may have entered the accessory module in connection with work done at the time it could have entered the accessory module at an earlier time. It was accepted that whenever the washer entered the module, “it is difficult to explain why it remained in a ‘harmless’ position for a long time before it changed position so that it limited the flow of oil” and it was not possible to determine when or how the washer first ended up in the module.

During the initial investigation of the main gear box at Bristow Norway, the Investigation had observed ”a number of small metal washers lying on a work table” and when asked, none of the employees present could explain where the washers belonged. The Investigation concluded that the risk of FOD during aircraft maintenance must be minimised and that it was possible at the time in question to have had better control over the relevant small parts.

It was noted that any washer with P/N MS20002-6 is within the EASA category "Standard Parts 12” for which MROs are required to be able to trace parts back to a particular helicopter but not to specific maintenance activity on it.

The narrative Conclusion of the Investigation was as follows:

The heat development and oil leakage in the main gearbox occurred as a result of a metal washer that had entered a scavenge oil passageway in the left input module and become jammed. This caused a substantial narrowing of the passageway. The Investigation believes it is likely that the washer entered the module in connection with maintenance and via the openings that are exposed when the generator is disconnected from the flange on the accessory module. The Investigation has not been able to establish when the washer entered the gearbox. The last maintenance where the washer may have entered was 487:35 flight hours before the incident. It was therefore concluded that the washer had been in the main gearbox for at least that long. The Investigation has shown that Bristow Norway has a potential for improvement in keeping track of consumables.

One Safety Recommendation was made based on the findings of the Investigation as follows:

- that the Norwegian Civil Aviation Authority (CAA-N) follow up the helicopter operators' procedures and routines related to FOD and FOD related to gearbox maintenance in particular. [2023/05T]

The Final Report was approved on 2 November 2023 and published online the following day.