A359, Brisbane Australia, 2022

A359, Brisbane Australia, 2022

Summary

On 27 May 2022, an Airbus A350-900 was about to be pushed back from its gate at Brisbane in order to taxi for departure when a refueller nearby informed the engineer responsible for the aircraft turnround that the pitot covers were still fitted and advised their removal before pushback. This engineer was found to have certified removal of the covers in the aircraft Technical Log and removed the corresponding warning placard from the flight deck without visual or verbal confirmation that they had been removed. Multiple aspects of the handling agent’s related performance and practices were found to be deficient.

Flight Details

Aircraft

Operator

Type of Flight

Public Transport (Passenger)

Flight Origin

Intended Destination

Take-off Commenced

No

Flight Airborne

No

Phase of Flight

Parked

Location - Airport

Airport

General

Tag(s)

Inadequate Airworthiness Procedures

HF

Tag(s)

Fatigue,

Maintenance Visual Inspection,

Procedural non compliance

GND

Tag(s)

Ramp crew procedures

Outcome

Damage or injury

No

Non-aircraft damage

No

Non-occupant Casualties

No

Off Airport Landing

No

Ditching

No

Causal Factor Group(s)

Group(s)

Aircraft Operation

Safety Recommendation(s)

Group(s)

None Made

Investigation Type

Type

Independent

Cite This Page

SKYbrary Aviation Safety. (December 21, 2024). A359, Brisbane Australia, 2022. EUROCONTROL.

Retrieved February 1, 2026

from https://skybrary.aero/accidents-and-incidents/a359-brisbane-australia-2022

UID: 35300

Copied!

COPY

Description

On 27 May 2022, an Airbus A350-900 (9V-SHH) being operated by Singapore Airlines on a scheduled international passenger flight from Brisbane to Singapore as SQ25 was about to be pushed back from its gate at Brisbane in order to taxi for departure when an uninvolved third party alerted those responsible for removing the pitot covers that they were still fitted and they were then removed. The lack of robust procedures for ensuring pitot cover removal before departure was noted to have previously been found in respect of a different aircraft operator using the same ramp service provider at the airport.

Investigation

An Investigation into the occurrence was carried out by the Australian Transport Safety Bureau (ATSB). Relevant recorded airport CCTV footage was available to support the accounts given of the oversight involved.

It was noted that the Licensed Maintenance Engineer involved had been employed as such at the aircraft engineering company he worked for - Heston MRO - since 2021 and was their regional manager for southeast Queensland. This post had responsibility for services provided at two other smaller airports, Gold Coast and Wellcamp which included licensed engineer cover for unscheduled absences at all three airports and storage and movement of aircraft at the Wellcamp. At Brisbane, the company was contracted to provide ramp services to a number of aircraft operators including Singapore Airlines.

What Happened

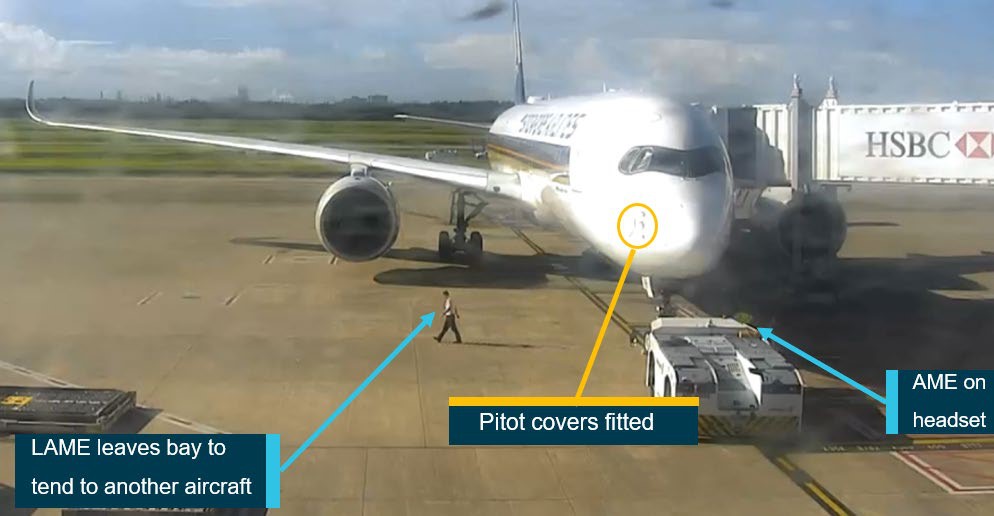

Two people were employed by the airline’s ramp service contractor at the airport. The licensed engineer referred to above was supervising a relatively new engineer employee whose responsibilities as ‘turnround coordinator’ during the two hours between arrival and departure included headset duties for the departure. The licensed engineer was also monitoring similar activity on an adjacent stand. Soon after the aircraft arrived, CCTV footage showed him taking the new engineer through the external aircraft inspection process and then personally fitting the required four pitot covers. He then went to the flight deck to check for any defect entries in the aircraft Technical Log (there were none) and made an entry in it recording the pitot covers being fitted and placed the corresponding warning placard on the central pedestal.

About 35 minutes prior to departure time, the First Officer conducted an abbreviated pre-flight external inspection during which he would have seen - and expected to see - the pitot covers in place. Five minutes later, the licensed engineer arrived back at the aircraft and discussed refuelling with his turnround coordinator and then spoke to the flight crew using the ground crew headset to confirm the required fuel load. Five minutes later, he returned to the flight deck, cleared the Technical Log entry for fitment of the pitot covers and certified the pre-flight check and then removed the pedestal warning placard and left the aircraft. He then went to his nearby vehicle and placed the warning placard on the dashboard. A few minutes later, he went to the front of the aircraft where the turnround coordinator had his headset plugged in ready for communication with the flight crew during pushback and engine start. After a few minutes conversation, he then said he was going to the adjacent stand to monitor the refuelling of the other aircraft.

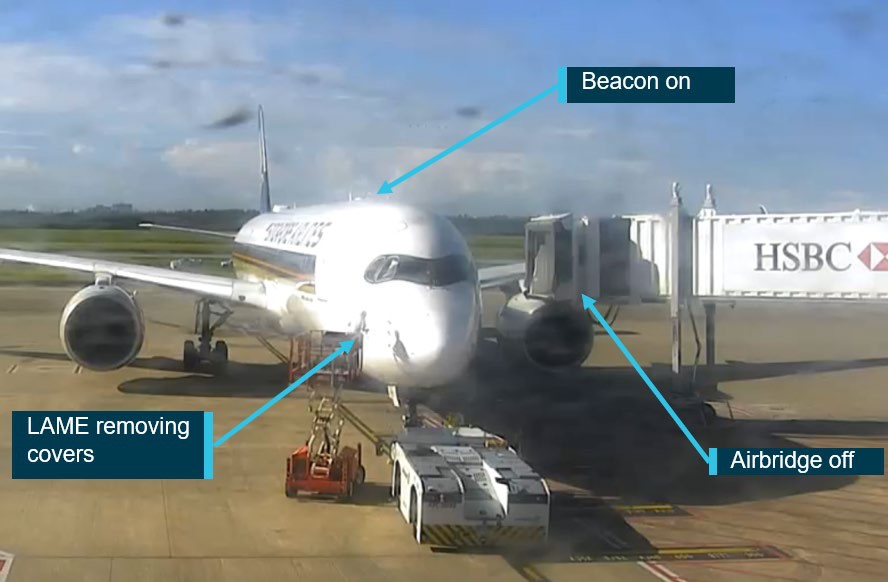

At about this time, an aircraft refueller tasked with this refuelling saw that although pushback of the A350 appeared to be imminent, the pitot covers were still fitted so immediately after the licensed engineer arrived he pointed this out. The latter returned to the A350 as the air bridge was being moved clear of the aircraft as the flight crew switched on the anti-collision lights and advised the turnround coordinator that they had obtained push back clearance from ATC. Having just been told by the licensed engineer that the pitot covers were still fitted, he informed the flight crew to standby whilst they were removed which was then done. The following three airport CCTV stills show final few minutes prior to the eventual departure.

The aircraft 4 minutes before pushback. [Reproduced from the Official Report]

2 minutes before pushback - the refueller pointing to the aircraft and telling the engineer that the pitot covers are still fitted. [Reproduced from the Official Report]

The engineer removing the covers with pushback delayed. [Reproduced from the Official Report]

Why It Happened

The Investigation made a comprehensive examination of the circumstances which enabled this sequence of events to occur and the Findings were separately presented in the form of factors which were considered to be either directly contributory and ones which increased risk.

Three Contributing Factors were formally documented, one of which was classified as a Safety Issue and is identified below as such:

- The licensed aircraft maintenance engineer certified for the removal of the pitot covers in the technical log and removed a warning placard from the flight deck without visual or verbal confirmation that the pitot covers had been removed.

- Heston MRO had not yet implemented a previously proposed and accepted method to account for tooling and equipment (such as pitot probe covers) prior to aircraft pushback. [Safety Issue]

- Maintenance personnel responsible for the aircraft departure did not conduct a final aircraft walk-around inspection. That inspection was the last procedural opportunity to identify that the pitot covers had not been removed.

Four Other Factors that increased risk were also formally documented, three of which were classified as Safety Issues and are identified below as such:

- The licensed aircraft maintenance engineer was undertaking dual roles as both regional manager and engineer. This increased the risk of a fatigue-related maintenance error occurring as a result of a significantly expanded workload in the months that preceded this incident.

- Heston MRO did not track the work-related hours of personnel with dual management and operational roles (including the licensed aircraft maintenance engineer) for fatigue calculation purposes. Therefore, there was an increased risk of a fatigue-related incident involving those personnel. [Safety Issue]

- The majority of Singapore Airlines flight crews (observed around the time of the incident) did not fully complete the required pre-flight walk-around inspections. [Safety Issue]

- Although suitable for use in most situations, the streamers attached to the pitot probe covers used for the Airbus A350 operations at Brisbane Airport provided limited conspicuity due to their overall length, position above eye height, and limited movement in wind. This reduced the likelihood of incidental detection of the covers, which is important during turnarounds. [Safety Issue]

All four identified Safety Issues were noted to have either already been addressed or a specific intention to address their content had been accepted.

The overall Safety Message from the Investigation was documented as follows

Airspeed is a critical flight parameter, which is particularly important to flight crew during takeoff and initial climb. It is the basis for their awareness of flight conditions such as the approach of aerodynamic stall and determination of critical decision points. This occurrence demonstrates how assumptions and procedural omissions can lead to unsafe conditions, in this case, the potential for an aircraft to commence a take-off with erroneous or absent airspeed indications due to the pitot probe covers remaining fitted.

Fatigue is a known factor in maintenance errors and can have a range of adverse influences on human performance. Therefore, it is important that organisations appropriately track all hours worked by safety critical employees to ensure they are receiving adequate rest and safeguard against the effects of fatigue.

Finally, this Investigation recognises the positive actions of the refueller, who was working on the adjacent bay and had identified that the pitot covers remained fitted. This serves as a reminder that all line personnel have a safety role and should always speak up if they see or feel that something is not right.

Safety Action

Singapore Airlines issued an Internal Notice to Airmen (INTAM) on 12 December 2023 to all its A350 pilots on the importance of adhering to standard operating procedures in relation to the completion of exterior checks.

Singapore Airlines instructed by Heston MRO in January 2024 to use pitot probe covers which have longer streamers attached to ensure better conspicuity.

Heston MRO implemented an additional procedure whereby a warning placard must be placed on the aircraft communications panel where the ground headset is connected.

The Final Report was published on 15 March 2024. No Safety Recommendations were made.